Die casting

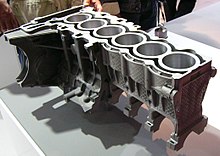

Die casting is a type of metal casting that forces molten metal into the empty space of the mold. The mold is made by using two hardened tool steel dies which are machined into shape. These work like an injection mold.

Most die castings are made from non-ferrous metals (meaning they do not have iron). These metals are zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on what type of metal is being cast, a hot- or cold-chamber machine is used.

The casting equipment and the metal dies are expensive. This means it is used only on things that need to be made a large number of times. It is simple to make things using die casting, and it has only four main steps. This helps keep the cost of the items lower. Die casting works well for many small- to medium-sized castings, which is why it is used to make more castings than any other casting process.[1] Die castings have a very good surface finish (compared to other types of casting) and consistent sizes.

References

change- ↑ "Die Casting vs Other Processes". Archived from the original on 2016-09-23. Retrieved 2016-09-16.